Cotton Processing Quality: Cotton, Seed, Lint, Trash

Contents

INTRODUCTION

The Cotton is a raw resource for different kind of products: cottonseed, cottonseed oil, cotton fiber, lint, textile products and etc. However, processing of raw cotton is very complex process and requires different steps, operations and inputs. Simultaneously, outputs (cotton products) and price of this products depend on various factors and quality indicators. For instances, moisture level and trash level of raw cotton.

PROBLEM DEFINITION

Outputs of cotton processing depends on different quality indicators which impact price of the product and eventually profit of the company. On the other hand, company supplies raw cotton from farmers based on the initial agreement before planting cotton and pays money based on the quality (trash level and moisture level) after harvesting. Initial agreement includes providing pesticides, irrigation systems, fertilizers, harvesting technologies and other agriculture services, which is calculated on a basis of cultivated land. As a problem, company should decide on the price (supplied raw cotton and output products) and estimate overall profit at the end of production cycles. Based on the estimated profit, company will decide on the pricing strategy, processing cycles and other costs.

DATA & METHODOLOGY

Data used for defining variables and equations was taken from the real life examples of the Cotton Processing Company operated in Azerbaijan. Prices and cost rates were defined based on the averages of existing data. Quality levels (trash and moisture) were defined based on standards in the cotton processing sector. Prices were defined using random variable within range that defined from Market data.

Vensim application was used for simulating dynamics of the process.

Time step for the model is selected as one day. However, eeach day should be considered as a supply cycle for one farmer or area of land. For simulation model 10 days or supplies were analyzed.

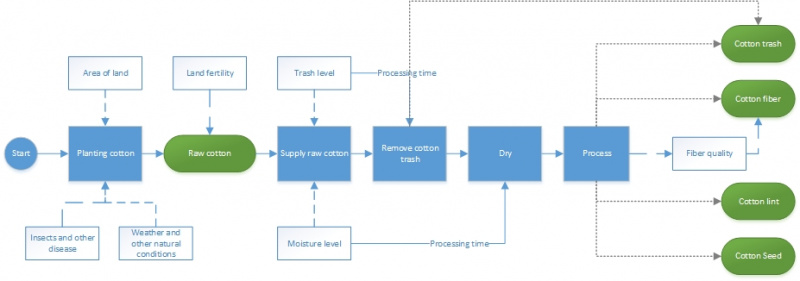

Following process map indicates general steps of the cotton processing starting from raw cotton and finishing with different cotton products

MODEL

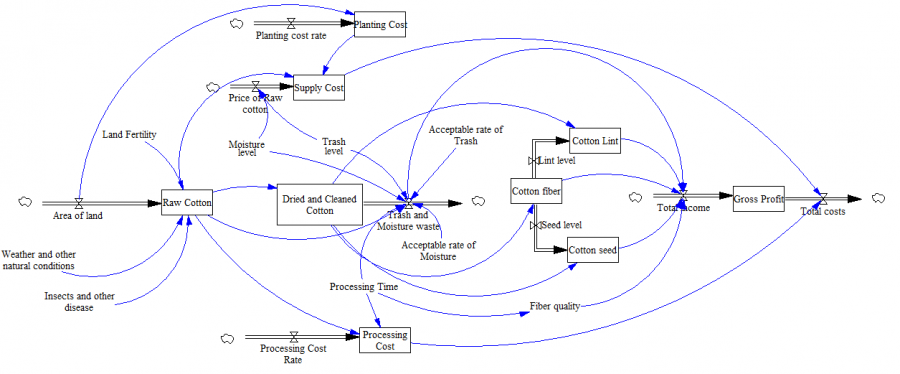

Stock flow diagram of the problem was described in the model below:

Following variables and equations was used in the model:

1. Weather and other natural conditions: This factors are random and uncertain. We can describe them using scale from 0 to 1. In ideal situation (1) all the conditions for fertility will be meet and output from land will be as expected (same as land fertility).

Expression: RANDOM NORMAL( 0 , 1 , 0.7 , 0.05 , 100 )

2. Area of Land: Company works with small, medium and large land owners. Minimum area of land is 50 hectares and maximum is 750 hectares.

Expression: RANDOM NORMAL( 50 , 750 , 400 , 50 , 100 )

3. Land fertility: Within range 1.50 and 2.80 tons per hectare.

Expression: RANDOM NORMAL( 1.5 , 2.8 , 2 , 0.1 , 100 )

4. Insects and other disease: This factor is random and uncertain. We can describe them using scale from 0 to 1. In ideal situation (1) all the conditions for fertility will be meet and output from land will be as expected (same as land fertility).

Expression RANDOM NORMAL( 0 , 1 , 0.7 , 0.05 , 100 )

5. Raw Cotton:

Expression: INTEG(Land Fertility*Area of land*Insects and other disease*Weather and other natural conditions,0)

6.Trash level:Raw cotton received from the farmer expected to have following level of trash.

Expression: RANDOM NORMAL( 10 , 18 , 15 , 0.5 , 100 )

7.Moisture level:Raw cotton received from the farmer expected to have following level of trash.

Expression: RANDOM NORMAL( 12 , 18 , 15 , 0.5 , 100 )

8.Dried and cleaned raw cotton:After drying and cleaning steps, remaining raw cotton wit acceptable level of trash and moisture will be moved to the next processing steps.

Expression: Raw Cotton-Trash and Moisture waste

9.Trash and Moisture waste:

Expression: Raw Cotton*(Moisture level + Trash level-5)/100

10.Planting cost rate:

RANDOM NORMAL( 300 , 550 , 400 , 25 , 100 )

11.Planting Cost: Agriculture services provided by the company like fertilizers, irrigation systems and etc. Estimated based on the area of cultivated land.Those costs will be excluded from supply cost.

Expression: Area of land*Planting cost ratee

12.Supply Cost:

Expression: Price of Raw cotton*Raw Cotton-Planting Cost

13.Processing Cost:Estimated based on the amount of raw cotton.

Expression: Processing Cost Rate*Processing Time*Raw Cotton

14.Price of Raw Cotton:500 USD per tones is normal price under conditions that trash and moisture level in total will not exceed limit.

Expression: 500*(100-Trash level + Moisture level-10)/100

15.Cotton Fiber Normally it is 40% of the processed cotton.

Expression: INTEG((1-Lint level-Seed level)*Dried and Cleaned Cotton,0)

16.Lint Level

Expression: RANDOM NORMAL(0.07, 0.15 , 0.1 , 0.02 , 100)

17.Seed Level

Expression: RANDOM NORMAL( 0.45, 0.53 , 0.47, 0.05 , 100 )

18.Cotton Lint

Expression: INTEG(Lint level*Dried and Cleaned Cotton,0)

19.Cotton Seed

Expression: INTEG(Seed level*Dried and Cleaned Cotton,0)

20.Processing Cost Rate:Estimated based on the amount of raw cotton.

Expression: RANDOM NORMAL(170, 200 , 180 , 10 , 100 )

21.Processing Time:Can be controlled by the company, it defines cycles of the production with each cycle fiber quality and processing costs increase.

Expression: 1

22.Fiber Quality:To certain extend processing cycles/time increase fiber quality.

Expression:IF THEN ELSE( Processing Time>2 , 1.6, 0.8*Processing Time)

23.Total Income:Price of each product is identified based on average market prices and random variable.

Expression:Fiber quality*RANDOM NORMAL(1600, 2000, 1800 , 30 , 100 )*Cotton fiber+Cotton seed*RANDOM NORMAL(150, 200, 170 , 10 , 100 )+Cotton Lint*RANDOM NORMAL(300, 450, 350 , 20 , 100 )+Trash and Moisture waste*50

24.Total Cost:Total cost of supplying and processing raw cotton.

Expression:Processing Cost+Supply Cost

25.Gross Profit:

Expression:INTEG(Total income-Total costs,0)

RESULTS

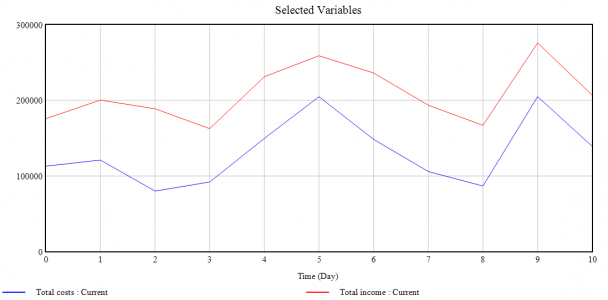

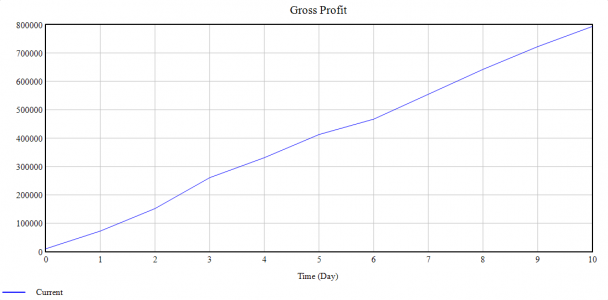

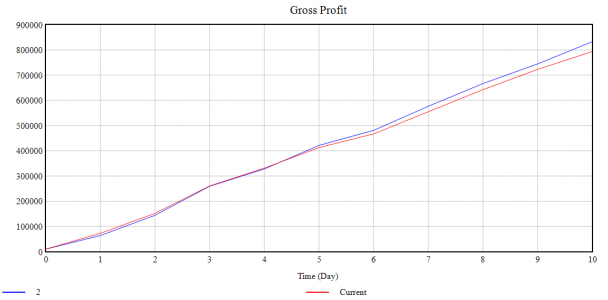

Following graphs indicate income, cost and gross profit of the company after accepted raw cotton from 10 farmers. As can be seen, income and cost fluctates but generally presents increasing trend. Gross profit of the company is expected to reach around 800,000 USD. In average 300-450 tonnes of Raw cotton received per day from the farmers.

Several variables can be controlled by managers in order to increase the Gross profit. We can increase Processing time (number of cycles in Ginning machine) which will result in increase of Fiber Quality. Consequently, gross profit will increase. As we can notice from the chart below there will be a slight increase in the Gross Profit, but this slight increase will result in significant change in the profit.

CONCLUSION

Simulation model was created for companies involved in the processing of raw cotton, based on the contractual terms with farmers. Those type of agreements is well known in the cotton processing countries, for example Azerbaijan. As a result of the simulation total Gross Profit can be estimated after certain received amount of Raw cotton. Several variables defined in the model can be used as a control tool by the companies:

- Different type of Raw cotton price calculation can be established by the company. In practice, it is estimated on the base price, taking into consideration trash and moisture level of supplied product.

- Acceptable levels of Trash and Moisture can be used, to define standard of the company for supply and processing of the raw resources.

- Processing time that impact fiber quality, can be changed in order to show impact on the income and consequently gross profit.

PERSPECTIVE for MODEL IMPROVEMENT

Several additional variables and parameters can be estimated, and included into the Model. For instance, planting costs can be defined as usage fertilizers, pesticids used, and other agriculture services. Those variables will also have impact on land fertility, will influence (decrease) environment factors and insects (diseases). Comsequently resulted in more Raw Cotton Output. On the other hand, this model can be implemented for other agriculture plants, suach as, wheat and grain.

CODE

REFERENCES

- CottonSeed Pricing Report, https://wholecottonseed.com/news/2018/04/05/cottonseed-pricing-report-march-2018/

- Food and Acriculture Organization of the United Nations, Cotton, http://www.fao.org/3/CA4076EN/CA4076EN_Chapter10_Cotton.pdf

- Valco, T. and others, THE COST OF GINNING COTTON – 2016 SURVEY RESULTS,http://journal.cotton.org/ncga/upload/THE-COST-OF-GINNING-COTTON-2016-FINAL.pdf